We are turnkey Robotics & Automation solution providers

for manufacturers & R&D labs from a wide range of industries

130+

AUTOMATION PROJECTS COMPLETED

80+

ROBOTICS PROJECTS

COMPLETED

205+

ROBOTS / COBOTS

SOLD

34+

YEARS OF EXPERIENCE

[ SINCE 1991 ]

500+

CUSTOMER

BASE

ISO

ISO 9001:2015

CERTIFIED

TECHNOLOGIES

Our expertise in a diverse range of technologies enables us to creatively integrate

various systems to build smarter, more sophisticated & more user-friendly solutions

Collaborative Robots

Mac has sold hundreds of cobots and implemented cobot based light-weight applications for customers, such as Honda & Dell.

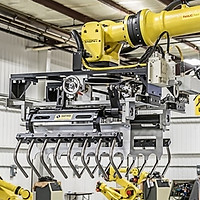

Industrial Robots

Mac has implemented industrial robots based heavy-weight applications for customers, such as Sobha Constructions & Ashirvad Pipes.

SPM

Mac has developed & deployed both light-weight SPMs & heavy-weight SPMs for products, such as Parachute Hair Oil & Gold Winner Cooking Oil.

AMR

Mac has deployed AMR fleets as part of our material logistics solution & AMR+Cobots mobile machine tending solution for customers such as Dell and Trelleborg.

Gantry

Mac has developed and deployed both light-weight & heavy-weight gantry based solutions for products such as Cadbury Bourn Vita & Britannia Marie Biscuits.

Industrial Automation

Mac, as a Rockwell Automation system integrator, has undertaken automation projects for customers such as Ashok Leyland & TVS Motors.

Software Apps

Mac's in-house team has developed several customized Windows PC applications as part of our robotics solutions for customers such as Mercedes-Benz and Baxter.

INDUSTRIES

Three decades of providing solutions for a wide range of industries enables us to

leverage our experience from one industry to solve challenges in other industries

Aerospace

Mac has undertaken automation projects for customers in the aerospace industry, such as Hindustan Aeronautics Limited (HAL) & Indian Space Research Organization (ISRO).

Automotive

Mac has deployed robotics solutions & undertaken automation projects for customers in the automotive industry, such as Toyota & Caterpillar.

Construction

Mac has implemented heavy-weight industrial robot based applications for customers in the construction industry, such as Sobha Constructions & Ashirvad Pipes.

Electronics

Mac has deployed light-weight cobot based solutions for our customers in the electronics industry, such as Schneider Electric & Bosch.

Education

Mac has deployed several Cobot based educator systems for our customers in the education industry, such as Manipal Institute of Technology & CMTI.

Food & Beverage

Mac has deployed robotics solutions, gantry based solutions & undertaken automation projects for our customers in the F&B industry, such as Britannia and Diageo.

FMCG / CPG

Mac has deployed robotic solutions, SPMs and undertaken automation projects for our customers in the FMCG/CPG industry, such as ITC Foods & Pepsi.

Mining, Oil & Gas

Mac, as a Rockwell Automation system integrator, has undertaken automation projects for customer in the mining & oil industries, such as Steven Rock & Aramco.

Personal Care

Mac has deployed gantry systems & SPMs for products in the personal care industry, such as Nihar Naturals Coconut Hair Oil & Parachute Aloe Vera Hair Oil.

Plastics

Mac has deployed cobots, SPMs, & vision quality inspection systems for customer(s) the injection moulding plastics industry, such as Manjushree Technopack Ltd (MTL).

Pharmaceutical

Mac has deployed cobot based solutions, SPMs & vision quality inspection systems for our customers in the pharmaceutical industry, such as Sanofi, DRL & Tata MD.

R&D Labs

Mac has developed robotic solutions & customized robotic apps for R&D divisions for our customers, such as Mercedes-Benz, Baxter & Bharath Electronics (BEL).

SOLUTIONS

Developing over 200 solutions for various distinct applications enables us to

leverage our experience from one application to solve challenges in other applications

AMR Logistics

Mac has sold AMRs and implemented fleets of AMRs as part of out material logistics solutions for our customers, such as Dell and Wipro.

AMR Machine Tending

Mac has deployed a high accuracy Cobot + AMR + Vision based Mobile Machine Tending Solution for our customers, such as Trelleborg.

Assembly

Mac has deployed various robotics based assembly solution for our customers in the automotive and electronics industry, such as Continental and Dell.

Customized Apps

Mac's in-house team has developed robotics apps, using Python, SQL & C, for Linux & Windows PCs, for our customers, such as Mercedes-Benz, Baxter, Sobha & BEL.

Customized End-Effectors

Mac has developed sophisticated & customized gripper solutions for our customers, such as Continental, DRL & Sobha Constructions.

Depalletizing

Mac has implemented heavy-weight SPMs that perform depalletization & truck loading operations for our customers, such as Kaleeswari Refineries Pvt. Ltd. (KRPL)

Dispensing

Mac has developed high accuracy cobot based glue dispensing & grease dispensing solutions for our customers in the automotive industry, such as Caterpillar.

End-of-Line Packing

Mac has deployed a large number of end-of-line packing solutions for various customers from a wide range of industries, such as ITC Foods, Britannia, Dr. Reddy's Lab & Sanofi.

Machine Tending

Mac has deployed a large number of cobot & robot based machine tending solutions for customers from a wide range of industries, such as Honda, Bosch & Autoliv.

Material Handling

Mac has developed various material handling solutions for our customers in the FMCG, F&B & Pharma industries, such as ITC, DRL & KRPL.

Palletizing

Mac has developed cobot based palletizers, with & without additional vertical 7th axis, for our customers in the FMCG & F&B industry, such as ITC Foods.

Pick & Place

Mac has implemented cobot, robot, vision, gantry & SPM based pick & place operations as part of most of our solutions for our customers.

Screwing

Mac has developed cobot based screwing solutions along with screw feeders for our customers in the electronics & automotive industries, such as Dell & Toyota.

Vision - Pick & Place

Mac has implemented Vision based pick & place robot solutions for our customers in the automotive, electronics and education industry, such as Honda, Dell & Infosys.

Vision - Quality Inspection

Mac has developed vision based quality inspection systems for our customers in the automotive, pharma & plastics industries, such as Valeo, Sanofi, Tata MD & MTL.

Welding

Mac has developed a cobot based welding solution over a flexible mobile structure for our customers in the automotive industry, such as Caterpillar.

CASE STUDIES

Learn more about our system designing & building capabilities by viewing a few of

our deployed solutions performing various applications in a wide range of industries

Cladding ACP Sheet - Routing & Sorting

Construction

Machine Tending

MAC Robotics & Automation implemented an Industrial Robot based Solution for ACP sheet handling for our client in the Construction Industry.

This solution features a 350 kg payload Industrial Robot integrated with a 20-meter horizontal 7th axis, two large pneumatic grippers, an automatic tool changer, a compressor, and a laser printer, all engineered to perform complex Machine Tending Operations for two ACP Sheet Cutting CNC Routing Machines, perform ACP child parts & scrap parts sorting operations and execute laser printing on the finished goods.

Biscuit Carton Packing - High Speed

FMCG / CPG / F&B

End-of-Line

MAC Robotics & Automation has successfully deployed a Cookie Carton Packing System as part of an End-of-Line (EOL) automation solution for clients in the Food & Beverage industry.

The system features a racetrack conveyor that arranges cookie packets into formation with the assistance of a pneumatic pusher, a gantry system that picks up the cookies from the racetrack conveyor and places them into two boxes simultaneously, and a conveyor that feeds open boxes for filling.

Pointer Tray Search, Pick & Assemble

Automotive

Assembly

MAC Robotics & Automation deployed a Cobot-based automation solution for a client in the Automotive Industry.

This advanced solution incorporates a Cobot equipped with a sophisticated gripper capable of performing multiple intricate tasks, including instrument cluster pointer tray arrangement, pointer searching, pointer pick-and-place, instrument cluster pick-and-place, and seamlessly feeding both the pointer and the instrument cluster to the assembly machine.

Pills Bottle Carton Pack, Inspect & Seal

Pharmaceutical

End-of-Line

MAC Robotics & Automation implemented a medical bottle carton packing solution, utilizing multiple Cobots, as part of an end-of-line automation system for a client in the Pharmaceutical Industry.

This highly adaptable solution is designed to handle bottles and carton boxes of varying sizes and dimensions, performing a range of operations, including bottle leaflet placement, bottle matrix formation, carton box formation, bottle carton packing, and carton box closing, sealing and vision inspection.

Cooking Oil Carton Depalletizer - High Speed

FMCG / CPG / F&B

Truck Loading

MAC Robotics & Automation deployed a Cooking Oil Carton Box Depalletizer as part of our comprehensive Truck Loading Automation Solution for clients in the FMCG and F&B sectors.

This solution is engineered to efficiently depalletize multiple variants of carton boxes, accommodating differences in weight and dimensions, and seamlessly feed them to the truck loading conveyor in a single-line configuration.

Bottle Machine Tending & Carton Packing

Plastics

End-of-Line

MAC Robotics & Automation has successfully deployed multiple Cobot-based Bottle Carton Packing Systems as part of an End-of-Line (EOL) automation solution for a client in the Plastic Injection Moulding industry.

The solution includes a custom-engineered mechanism that collects plastic bottles from the injection moulding machine, forms them into a matrix, and transfers them to the Cobot for precise and efficient dual-layer carton packing operations.

10+ Cobot Machine Tending Applications

Automotive

Machine Tending

MAC Robotics & Automation has successfully implemented a range of Cobot-based Machine Tending Solutions for clients across various industries.

This video showcases diverse gripper designs and modifications that have been engineered to meet the unique requirements of each machine tending application.

Additionally, vision-based pick-and-place operations have been integrated to address specific challenges in select applications, ensuring precision and adaptability.

Candy Bottle - Inspect & Pack - High Speed

Plastics

End-of-Line

MAC Robotics & Automation deployed a Bottle Container Packer and Inspector as part of our End-of-Line Automation Solution for clients in the Plastics Manufacturing Industry.

This solution is designed to perform multiple essential operations, including container erection, matrix formation, packing, sealing, and inspection of all containers for surface defects using an AI-powered Vision Inspection system integrated with a rejection mechanism.

Medical Vials Carton Pack, Inspect & Seal

Pharmaceutical

End-of-Line

MAC Robotics & Automation implemented a Vial Box Packing Solution, utilizing multiple Cobots, as part of an End-of-Line Automation system for a client in the Pharmaceutical industry.

The solution involves multiple Cobots performing a series of intricate operations, including box formation, honeycomb formation, honeycomb box insertion, vial matrix formation, vial placement into the honeycomb structure, vial pressing, leaflet placement, box closing, and vision inspection.

Bottle Inspection, Tray Form, Pack & Seal

Plastics

End-of-Line

MAC Robotics & Automation deployed a Bottle Container Packer and Inspector as part of our End-of-Line Automation Solution for clients in the Plastics Manufacturing Industry.

This solution is designed to perform multiple critical operations, including carton tray formation, container matrix formation, packing, sealing, and inspection of all containers for surface defects using an AI-powered Vision Inspection system integrated with a rejection mechanism.

Grease Dispenser - Movable Structure

Automotive

Dispensing

MAC Robotics & Automation deployed a Cobot based automation solution for a client in the Automotive Industry.

This solution features an upside-down mounted Cobot that performs precise sealant dispensing operations.

The system is equipped with an overhead mount that can be rotated over the production line during operations and moved away to allow seamless transfer of large materials along the production line.

Mobile Machine Tending - 4 CNC Machines

Automotive

Machine Tending

MAC Robotics & Automation implemented a Mobile Machine Tending application, integrating a Cobot, an Autonomous Mobile Robot (AMR), and a Vision System.

In this solution, the system autonomously navigates to four different CNC machines to perform machine tending operations, utilizing the Vision System to execute high-precision pick-and-place tasks with accuracy and efficiency.

Potato Chips Carton Sorting & Palletizing

FMCG / CPG / F&B

End-of-Line

Mac Robotics and Automation deployed a Cobot-based automation solution as part of the end-of-line automation solution for a client in the Food & Beverage Industry.

In this solution, a Cobot, along with a vertical 7th axis and barcode scanners, performs sorting operations based on the barcode data and palletizes the carton in correct pallet. This solution is flexible as it can work with cartons boxes of various dimensions and weights and arrangement patterns.

Robotics & Automation Educator - Industrial

Education

Training

MAC Robotics & Automation has deployed multiple Cobot Educators systems (Industrial version) for clients in the education and manufacturing sectors.

The training focuses on applications commonly used in manufacturing industries, such as robot pick-and-place operations, robot sealant dispensing, conveyor control & tracking, and robotics/PLC programming, HMI designing, pneumatic gripper control, equipping learners with practical skills essential for real-world industrial environments.

Seat Belt Buckle Indexer SPM & Feeding

Automotive

Machine Tending

MAC Robotics & Automation deployed a Cobot-based automation solution for a client in the Automotive Industry.

This solution features a Cobot that performs precise Pick & Place operations for Seat Belt Buckles, seamlessly feeding them into the Laser Marking Machine using an in-feed rotary indexer mechanism.

Eye Lens Manufacturing - UV Treatment

Medical

Pick & Place

MAC Robotics & Automation deployed a Cobot-based automation solution for an eye lens treatment operation for a client in the eyewear industry.

In this solution, the Cobot, enclosed in a protective suit to ensure a contaminant-free environment, seamlessly picks up lenses from the input conveyor, immerses them in multiple liquid solutions for treatment, and precisely places them back onto the output conveyor post-treatment.

Vials End-of-Line Pack & Inspect

Pharmaceutical

Machine Tending

MAC Robotics & Automation implemented a Cobot based Vial Box Packing Solution as part of an End-of-Line automation system for a client in the Pharmaceutical industry.

The solution involves a series of operations where a Cobot picks up vials containing different reagents from multiple input feed trays, inserts the correct combination of vials into the box, and performs vision inspection to verify the accuracy of the box’s contents.

Medical Vials Filling - Capping & Uncapping

Pharmaceutical

Machine Tending

MAC Robotics & Automation deployed a Vial Handling Cobot Solution for a client in the Pharmaceutical industry.

In this solution, a Cobot picks up multiple empty vials from the input tray, rotates to remove the caps, places the vials into the filling machine, retrieves them after the filling process, rotates to secure the caps back onto the vials, and finally places the capped vials in the output tray.

Medical Vials End-of-Line Pack & Inspect

Pharmaceutical

End-of-Line

MAC Robotics & Automation implemented a Vial Box Packing Solution, utilizing multiple Cobots, as part of an End-of-Line Automation system for a client in the Pharmaceutical industry.

The solution involves multiple Cobots performing a series of intricate operations, including box formation, honeycomb formation, honeycomb box insertion, vial matrix formation, vial placement into the honeycomb structure, vial pressing, leaflet placement, box closing, and vision inspection.

Robotics & Automation Educator - High Tech

Education

Training

MAC Robotics & Automation has deployed multiple Cobot Educator systems for clients in the education and manufacturing sectors.

These systems empower students and employees to gain hands-on experience with cutting-edge technologies, including Cobots, Grippers, Industrial PLC & HMI, Pneumatics, Conveyor Systems, 2D & 3D Vision Pick & Place, Joystick Control, Python Robotics Programming, and Raspberry Pi Interface.

Pills Bottle Carton Form, Inspect, Pack & Seal

Pharmaceutical

End-of-Line

MAC Robotics & Automation implemented a medical bottle carton packing solution, utilizing multiple Cobots, as part of an end-of-line automation system for a client in the Pharmaceutical Industry.

This highly adaptable solution is designed to handle bottles and carton boxes of varying sizes and dimensions, performing a range of operations, including bottle leaflet placement, bottle matrix formation, carton box formation, bottle carton packing, and carton box closing, sealing and vision inspection.

SERVICES

Our comprehensive range of services enables us to provide end-to-end turnkey

solutions offering convenience, faster project completion & cost savings for our clients

Consultation

Understand customer needs, conduct plant/site study, assess feasibility & ROI, create solution concept & propose detailed technical & commercial offer.

Concept Design

Develop detailed 3D model of system, run simulation, estimate cycle times, run FEA analysis, create electrical/logic/network schematics & integrate safety systems.

Proof of Concept

Create a real-world simulation of complex operations/movements to understand the feasibility of an application, particularly the cycle-time, accuracy and repeatability.

System Integration

Use our expertise in integrating Robots, Cobots, AMRs, Grippers, PLCs, HMIs, Conveyors, Pneumatics, Servo/Stepper motors etc. to meet your project goals.

Machine Build & Test

Procure & manufacture components, assemble/integrate the mechanical, electrical & software systems, run tests & pass the IFAT & CFAT requirements

Installation

Disassembly, packing, loading & transporting system to client's location. Unloading, assembly, integration & commissioning at client's location.

Training

Preparation of training material, such as user manual, tutorial ppts/videos and troubleshooting guides. Conduct hands-on training for the end-users/operators.

After-Sales Support

Provide Annual Maintenance Contracts (AMC) & Preventative Maintenance Contracts (PMC), replace parts, & bring system back to operating condition with minimal downtime.

ABOUT US

"Our mission is to empower manufacturers by providing intelligent,

tailored robotics & automation solutions that lower operational costs,

fuel growth, & make advanced robotics accessible for businesses of every size"

Overview

MAC Robotics & Automation is a premier ISO 9001:2015 certified company offering turnkey solutions in Industrial Automation, Robotics, AI, and Smart Manufacturing. With over 34+ years of expertise, a dedicated team of 60+ professionals, and advanced facilities in Bangalore, MAC delivers end-to-end, technology-driven solutions. The company also supports customer training, product testing, and proof-of-concept development through its in-house technical laboratory.

Our Story

Founded in 1991 by Mr. J. Nagarajan, who had five years of experience at the Fanuc CNC Machine Service Center, the company began as a Computerized Test and Repair Center for CNC Controllers and Servo Drives, serving the Automotive, Aerospace, and Engineering industries with a dedicated five-member team.

1991

In 1996, the company became an authorized system integrator of Rockwell Automation and began executing PLC and SCADA-based automation projects for Tier-1 clients in the Automotive and Food & Beverage industries, including leading names such as TVS and Sundaram Fasteners Limited

1996

In 2006, the company became an authorized distributor of Rockwell Automation and, in addition to the distribution business, began executing numerous Servo Drive projects for Machine OEMs across India, strengthening its presence in the industrial automation landscape.

2006

In 2012, the company expanded internationally, completing projects in Thailand, China, Myanmar, and the UAE. It delivered numerous Food & Beverage and Mining solutions for global clients, including Rexam and Steven Rock, strengthening its presence in the international automation market.

2012

In 2016, the company became a distributor of collaborative robots such as Universal Robots and launched robot integration projects for automotive and FMCG clients, including Honda, Bosch, and ITC. It also began developing gantry-based Special Purpose Machines (SPMs), significantly enhancing its range of advanced automation solutions.

2016

In 2018, the company launched vision-based robotics projects and robotics software development. It also began providing advanced automation solutions to R&D centers, including clients like Mercedes-Benz, expanding its expertise in cutting-edge robotic technologies and strengthening its position in the evolving automation industry.

2018

In 2021, the company expanded its portfolio by introducing AMR-based solutions and pharmaceutical projects. It also undertook heavy-weight Special Purpose Machine (SPM) projects, reinforcing its expertise in delivering advanced, high-precision automation solutions across critical industries and strengthening its position in the automation market.

2021

In 2024, the company focused on heavy-weight industrial robot applications for the international market. By serving clients such as Sobha Construction, it enhanced its expertise in handling large-scale robotic automation projects, strengthening its global presence and commitment to delivering robust, high-capacity automation solutions worldwide.

2024

Facility

Mac Robotics & Automation's headquarters in Peenya, Bangalore, is a state-of-the-art, ISO 9001:2015-certified facility. It houses design, fabrication, assembly, and testing under one roof. The team develops custom machines, fabricates components, and conducts IFAT and CFAT. On-site POCs support innovation, while project management ensures seamless execution. A dedicated inventory area enables efficient spare part management, supporting streamlined production and after-sales service.

Leadership Team

Mr. Nagarajan J

Founder & Managing Director (MD)

Mr. Nagarajan founded the company in 1991 and continues to play an active role in its senior leadership. Over the years, he has also taken on ownership roles in ten companies across sectors such as solar energy, CNC machines, robotics, and electronics, alongside his business partners. Collectively, these ventures manage an annual turnover of approximately $33 Million USD and employ over 500 people across multiple countries.

Mr. Manikantan N

Chief Business Development Officer (CBDO)

Mr. Manikantan, Chief Business Development Officer (CBDO), brings over 25 years of experience in industrial automation, with a strong focus on discrete manufacturing. Since joining Mac in 2000, he has played a key role in engineering leadership and business growth. An expert in concept design for gantry systems, SPMs, and robotic solutions, he drives initiatives to expand capabilities and execute complex projects.

Mr. Balasubramanya KV

Chief Operating Officer (COO)

Mr. Balasubramanya, Chief Operating Officer (COO), brings over 37 years of experience, including leadership roles at Yokogawa and Toyota Motors. He has led major process automation projects in India and abroad. At MAC, he focuses on operational excellence and strategic execution, driving growth through professionalization, streamlined project management, and continuous improvement across all facets of the organization.

Mr. Padmanaban M

General Manager - Robotics & Automation Sales

Mr. Padmanaban, General Manager – Robotic & Automation Sales, brings over 25 years of experience and has been with MAC since 2001. Specializing in industrial automation and robotics sales and consultancy, he expertly understands complex customer needs and delivers tailored solutions. His deep industry knowledge ensures clients receive innovative, practical technologies that optimize operations and drive long-term efficiency and performance.

Mr. Pateel GS

Head - Business Solutions Specialist

Mr. Pateel GS is a Business Solutions Specialist with over 18 years of experience, including 16 years at Mac. As a Robotics Engineer and Industrial Automation Specialist, he excels in Service Engineering, Solution Architecture, and Project Management. Known for strong problem-solving skills, he delivers innovative solutions, managing projects from concept to completion while optimizing processes and boosting performance.

Mr. Ramesh B

Project Finance Manager

Mr. Ramesh B is a Project Finance Manager with over 25 years of experience, all with Mac. With a strong finance and accounting background, he specializes in project finance management, planning, budgeting, monitoring, compliance, and reporting. He provides expert guidance to the company, helping manage finances in smart ways and ensuring efficient fund management for handling complex projects with ease.

Mr. Augustine ALB

Senior Project Manager - Robotics & AMRs

Mr. Augustine ALB is a Senior Project Manager – Robotics & AMRs – with over 10 years of experience, including 5 years at MAC. A specialist in robotics applications, vision systems, and autonomous mobile robots (AMRs), he brings deep expertise in robotics repair, industrial automation, and system architecture. He excels in project management and currently leads a team of 10, delivering advanced automation solutions.

Mr. Chetan RP

Senior Project Manager - Automation & Vision

Mr. Chetan RP is a Senior Project Manager – Industrial Automation – with over 10 years of experience, including 4 years at MAC. He has deep expertise in process automation, industrial networking, SCADA systems, HMI, PLCs, panel and automation architecture, industrial robot servicing, and vision systems for quality inspection and robotic pick-and-place. He leads a team of 10, delivering smart, scalable automation solutions.

Mr. Govindaraju GM

Head - Machine Manufacturing & Assembly

Mr. Govindaraju GM, Head – Machine Manufacturing & Assembly, brings over 25 years of experience, including 3 years at MAC. He leverages strong mechanical expertise to add value in machine building, materials management, parts manufacturing, assembly, and system testing for IFAT and CFAT. Responsible for on-site installation and prove-out, he leads a team of 7 to ensure high-quality delivery and operational excellence.

Mr. Arvind M

Head - Information Technology & Networks

Mr. Arvind M, Head of Information Technology & Networking, has led IT and networking projects for clients including Mercedes-Benz, AMR Trelleborg, Dell, and Aramco. An expert in enterprise IT networking and management for large organizations, he ensures seamless project execution. In addition to technical leadership, he supports administrative and HR activities, contributing to smooth organizational operations across teams.

Mr. Dasharath S

Head - Machine Concept Design

Mr. Dasharath S is a Machine Concept Designer with over 9 years of experience and deep expertise in mechanical CAD design. Combining creative concept development with solid engineering knowledge, he delivers effective machine solutions tailored to customer needs. His specialization includes robotics, fixtures, SPMs, AMRs, gantry systems, and vision mechanical systems, consistently driving innovation and precision in every design project.

Mr. Punith DSK

Head - Electrical Design & Panel Assembly

Mr. Punith DSK is Head of Electrical Design & Panel Assembly with over 10 years of experience. He specializes in electrical architecture, planning, panel design using AutoCAD 2D, sensor integration, and power management. Responsible for electrical panel assembly and cable management, he applies his expertise to solve complex electrical challenges in every project, ensuring efficient, reliable, and high-quality electrical systems.

Certification

"Mac Machine Tools & Automation,

388/A, 3rd Main, 10th Cross, Ganapathy Nagar,

4th Phase, Peenya Industrial Estate, Bengaluru

(Bangalore), Urban - 560058, Karnataka, India"

has implemented and maintains a Quality Management System for

"Providing solutions for industrial automation robotics and smart manufacturing, manufacturing and supply of solar photovoltaic monitoring system, distribution of electrical components"

Which was audited and found to be in compliance according to the Standard

ISO 9001:2015

Clients

Automotive

Electronics & IT

Pharma & Medical

FMCG, CPG & F&B

Other Industries

Client Testimonials

"Mac did impressive work in

Robotic Cell Digitization Project by establishing a new method by which OT systems get connected to our server in a secured way for real time DAQ. The real-time production data visualization reports generated by the team is appreciated"

- Vishnu Vihari,

Project Manager - PE,

TVS MOTORS, India

“Mac's team exhibited high professionalism in delivering high quality deliverables of PLC based Automation System. They delivered the project as per assigned project schedule”

- Kushal Thakkar,

Head - Central E&A,

JINDAL STEEL, OMAN

“Mac’s high-quality deliverables during CR22 project of PLC based Automation System with real-time Production Monitoring Solution is well appreciated. We appreciate the Project Management & Engineering Team”

- Naseer Bustani,

General Manager,

STEVEN ROCK LLC, UAE

CONTACT

Let's find the right solution for you. Get in touch with us.

Mr. Puneeth N Kumar

Sales Engineer, CSRC & QMS Support

Email: salessupport@macindia.in

Phone: +91-7349409559

Mr. Manikantan N

Chief Business Development Officer

Email: manikantan@macindia.in

Phone: +91-9845579794

Address

Mac Machine Tools And Automation - Unit 3,

No 48/1, near Thigalarapalya Main Road, 2nd Stage, Kalika Nagar, Peenya, Bengaluru, Karnataka, India - 560058

Opening Hours

Mon - Fri

9:00 am – 5:00 pm

Saturday

9:00 am – 1:00 pm

Sunday

Closed

Social Media

Company website: